Our professional fabrication model integrates meticulous design reviews, quality material procurement, precision cutting and forming, expert welding, thorough inspection, advanced surface finishing, and reliable delivery. Every step is executed by skilled professionals using modern equipment, ensuring superior quality, safety, and client satisfaction across all fabrication projects.

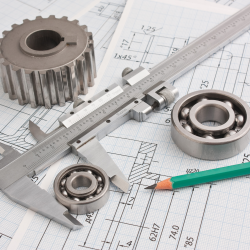

Thorough review of client specifications, drawings, and feasibility studies to ensure optimal design for fabrication.

Sourcing of high-quality raw materials from approved vendors, with strict adherence to material specifications and traceability.

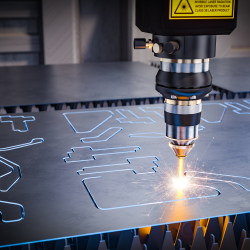

Precision cutting (laser, plasma, oxy-fuel) and forming (bending, rolling) of materials using advanced machinery.

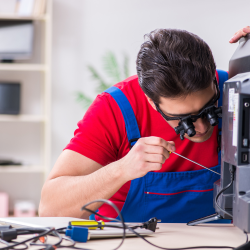

Expert welding processes (MIG/MAG) and assembly by certified welders, ensuring structural integrity and precise fit-up.

Rigorous in-process and final inspections, including non-destructive testing (NDT), dimensional checks, and visual inspections.

Application of appropriate surface treatments (painting, galvanizing) and finishing processes for enhanced durability and aesthetics.

Secure packaging, timely delivery, and optional on-site technical support for installation.